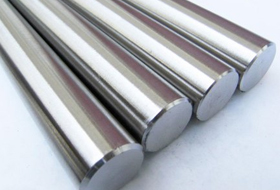

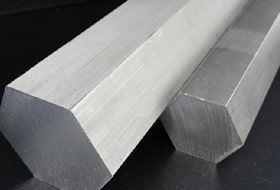

Stainless Steel 422 Angle Bars, Stainless Steel 422 Export Bright Round Bar, Stainless Steel 422 Threaded Bars, 422 Stainless Steel Round Bar Finishes, SS 422 Bars Stockholder in Mumbai India, 422 Stainless Steel Round Bar Trader, 422 SS Cold Rolled Bars, 422 Stainless Steel Rod, Stainless Steel 422 Bars and Rods Distributor, SS 422 Export Polish Round Bar, Stainless Steel 422 Triangle Bars, Stainless Steel 422 Round Bars Stockists, Stainless Steel 422 Round Bars in India, SS 422 Channel Bar, Stainless Steel 422 Hot Finished Round Bar, 422 Stainless Steel Hot Rolled Bars & Rod, 422 Stainless Steel Polish Bars & Rods Wholesale Trader, ASTM A276 Stainless Steel 422 Half-Round Bars, 422 SS Square Bar Price, SS 422 Cold Drawn Round Bar, ASTM A276 Stainless Steel 422 T-Bar, Stainless Steel 422 Round Bar Dealer, SS 422 Cold Finish Bar, SS 422 Industrial Bars, 422 Stainless Steel Bar Price Per Kg in India.

422 Stainless Steel Round Bar, Stainless Steel 422 Bright Bar, 422 stainless steel bar, ss422, Stainless Steel 422 Round Bars, SS 422 Round Bar, Stainless Steel 422 Round Bar, AISI 422 Round Bar, 422 Stainless Steel Rods, Stainless Steel 422 Bright Bar Supplier in Mumbai, India.

Reliable Overseas is a standard distributor of Stainless Steel 422 Bright Bars, which are relatively resistance to chloride ion stress-corrosion cracking. These SS 422 Bright Bars as well have excellent mechanical characteristics at high temperatures. Alloy 422 Bright Bars is acknowledged amongst our clients due to its features like high tensile strength and optimum quality. These Grade 422 Bright Bars are used in Oil & Gas Processing and Extraction, Power Generation, Automotive, Nuclear, Aerospace, etc. Type 422 Bright Bars must be welded in the stress-equalized form, 885 Degree C (1625 Degree F) heat treatment, and age hardened and solution treated after welding has been finished.

422 Stainless Steel Bright Bars has outstanding features down to cryogenic temperatures, and so is used in extrusion dies, forming tools, and so on. Stainless Steel UNS S42200 Bright Bars has outstanding welding features, that are resistant to post-weld age cracking and can be voluntarily age hardened and worked. However, the age-hardened state of Stainless Steel WNR 1.4935 Bright Bars gives improved chip action on chip breaker tools and creates an improved finish.

422 stainless steel suppliers, Stainless Steel 422 Bright Bar Suppliers, 422 Stainless steel, Stainless Steel 422 Round Bar Supplier, ASME SA276 Stainless Steel 422 Polished Bright Bar Trader, Stainless Steel 422, SUS 422 Round Bar Stockists, SS 422 Bright Round Bar Exporter in India.

However, the poor age-hardening of SUS 422 Bright Bars retort allows welding and annealing deprived of impulsive toughening during cooling and heating. Stainless Steel 422 Bright Rods has excellent oxidation resistant all the way through its suitable temperature range. Meanwhile, Alloy 422 Bright Rods is carefully tested by specialists before the final shipment for to make sure to give the perfect product at customers end.

422 Stainless Steel Round Bars, Stainless Steel 422 Forged Bars, Stainless Steel 422 Bright Bars, SS 422 Polish Round Bar Dealer, DIN 1.4742 Rectangle Bars, Stainless Steel 422 Threaded Bars Distributors, SS 422 Round Bar Price, 422 Stainless Steel Round Bar Manufacturer in India.

Equivalent Grades of 422 Stainless Steel Round Bar

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | EN |

| SS 422 | 1.4742 | S42200 | SUS 422 | 442S19 | X10CrAlSi18 |

SS 422 Chemical Composition

| Weight% | C | P | Si | Ni | V | Fe | Mn | S | Cr | Mo | W | Cu |

| Alloy 422 |

0.20-0.25 | 0.040 max | 0.20-0.60 | 0.50-1.0 | 0.17-0.30 | Bal | 1.0 | 0.030 max | 11.0-13.5 | 0.75-1.25 | 0.75-1.25 | 0.50 |

Mechanical Properties of 422 Stainless Steel Round Bar

| Material | Condition | 0.2 % Yield Strength (ksi) | Ultimate Tensile Strength (ksi) | % Elongation in 2" | % Reduction of Area | Hardness HB |

| Alloy 422 | Hardened & Tempered (AMS 5655) | 140 | 115 | 13 | 25 | 293-341 |

Stainless Steel 422 Bright Bars FAQs

What is 422 stainless steel?

Type 422 (S42200) offers exceptional performance in high-temperature environments, withstanding temperatures up to 1200°F. This makes it an ideal choice for the aerospace and power generation industries, where components must endure both mechanical stress and extreme temperatures. Its heat treatability allows engineers to

customize its strength for specific applications, creating an optimal balance of high strength and low weight.

Compared to Type 403, Type 422 stainless steel excels with better high-temperature resistance and also boasts the highest electrical conductivity among wrought martensitic stainless steels. It resists scaling and oxidation, ensuring durability and longevity in challenging conditions.What is the steel equivalent to 422?

Equivalent materials to grade 422 stainless steel are: AISI 422. AMS 5655. ASTM A565.

Stainless steel 422, also known as alloy 422, AMS 5655, or UNS S42200, has several equivalent materials, including: AISI 422, ASTM A565, DIN 1.4935, GE B50A125E, SAE 51422, and SAE J467.

What is the hardness of AISI 422?

Type 422 stainless steel can be heat treated to achieve a wide range of hardness values depending on the specific heat treatment process.

Annealed Condition: In the annealed state, Type 422 typically has a hardness of Rc 21 to 25. This relatively lower hardness allows the material to be more easily machined, with characteristics similar to Type 420 stainless steel.

Quenched and Tempered Condition: After quenching and tempering, Type 422 typically achieves a hardness of Rc 45 to 50, depending on the exact tempering temperature and process. This higher hardness significantly improves the material's strength and wear resistance but can reduce its machinability.

The machinability of steel in the annealed condition is good and is comparable to other martensitic stainless steels, like Type 420, due to its lower hardness. However, once it has been quenched and tempered to higher hardness levels, the material becomes more difficult to machine, requiring specialized tooling and techniques to manage the increased hardness.

What are common applications of 422 Stainless Steel?

Type 422 (S42200) martensitic stainless steel is highly valued for its ability to retain mechanical strength at temperatures up to 1200°F (649°C). This property makes it ideal for applications in demanding, high-temperature environments, particularly in the aerospace and power generation industries.

Type 422 also possesses the highest electrical conductivity among wrought martensitic stainless steels, which can be beneficial in certain applications. It is also resistant to scaling and oxidation in high-temperature environments, further extending its service life in applications involving prolonged heat exposure.

Typical Applications:

- Steam Turbine Buckets and Blades: Where mechanical strength must be maintained under high temperatures and steam exposure.

- High-Temperature Bolting: Used in situations where bolts must retain their strength and resist oxidation at elevated temperatures.

- Valve Components (Valve Bodies and Trim): Especially in high-temperature and high-pressure systems, such as in power plants.

By providing high strength, good corrosion resistance, and reliable performance at elevated temperatures, Type 422 is a preferred material for components that must withstand both mechanical loads and extreme heat.

| Material | Condition | 0.2 % Yield Strength (ksi) | Ultimate Tensile Strength (ksi) | % Elongation in 2" | % Reduction of Area | Hardness HB |

| Alloy 422 | Hardened & Tempered (AMS 5655) | 140 | 115 | 13 | 25 | 293-341 |

Export Destination of Stainless Steel 422 Bright Bars, Rods

Ukraine, Ghana, Hungary, Serbia, Sri Lanka, Puerto Rico, Netherlands, Chile, Switzerland, Czech Republic, Oman, Egypt, Saudi Arabia, Gabon, Kenya, Australia, Norway, Germany, Austria, Jordan, Slovakia, Bangladesh, Denmark, Morocco, Singapore, United States, Trinidad & Tobago,Tunisia, Qatar, Venezuela, Lithuania, Thailand, Tibet, Russia, Estonia, Pakistan, Poland, Kuwait, Nigeria, Peru, Mongolia, Hong Kong, Lebanon, Ireland, Azerbaijan, Ecuador, Brazil, Taiwan, Angola, Chile, Costa Rica, Belgium, Iran, Mexico, Canada, Namibia, Turkey, Poland, Zimbabwe, Sweden, Yemen, Belarus, Finland, Iraq, Iran, Bulgaria, China, Malaysia, Indonesia, Nepal, New Zealand, Macau, Philippines, Colombia, United Kingdom, France, Gambia, Israel, Bahrain, Kazakhstan, South Korea, United Arab Emirates, Vietnam, Romania, Spain, Mexico, South Africa, Nigeria, Italy, India, Japan, Croatia, Greece, Algeria, Bhutan, Afghanistan, Argentina, Portugal, Bolivia, Libya.